Debonair Ltd. & Orbitex Knitwear Ltd.

As a strategic move, Debonair Group has planned to extend its production capacity through diversification of product range. This new venture would enable Debonair Group to strengthen its capacity in making specialized padding and quilted materials and will help us to execute jacket manufacturing orders in time due to in-house padding and quilting manufacturing facilities. To setup this state-of-the-art manufacturing plant, we have appointed a well-known architectural firm to oversee and complete the project on time, and sourced capital machineries form Korean, Japan, UK and other European countries. Implementation of this project is now well underway and commercial production is scheduled to begin by early 2017.

After successful implementation of padding and quilting project, we would be able to offer better services to our existing clientele such as H&M, K-mart, TEMA (Turkey), Best Seller, Jack and Jones, Benetton (Italy) Charles Vogele (Germany), Next (UK) etc. we are also expecting to receive more and more top-branded quilted and padded jacket export orders from various reputed buyers from Europe and America. In response to practicing towards sustainable manufacturing, Debonair has also taken keen initiatives to protect mother environment through installing efficient and effective Waste Management program integrated into day-to-day manufacturing activities.

Production Capacity

- Average 50 SMV per Jacket production capacity per month 650000 pcs.

- 10% per month bottom production Average 30 SMV average 60000 pcs

Our Products

- Fake down Jkt

- Real Down Jkt

- Padding Jkt

- Soft shell Jkt

- Wind Breaker Jkt

- Rain wear / Seam selling Jkt

- Long Pant

- Cargo Pant.Overall etc

Buyers

THE NORTH FACE, VF Timberland, H&M, Benetton, VF Dickies, VF VANS, VF NAPAPIJRI, C&A, KIABI, Camel Active, CAMP DAVID, 4F, BESTSELLER., TOM TAILOR, Kmart, Inditex, NAUTICA.

Machineries

| Machine code(u-1) | Machine name | Type code | Machine type | Machine QTY |

| 01 | Single needle | 01 | Lock stitch | 2037 |

| 02 | Needle feed | 403 | ||

| 03 | Top feed | 25 | ||

| 04 | Cuff rolling | 11 | ||

| 05 | Long head 1 needle | 39 | ||

| 06 | Long head 2 needle | 02 | ||

| 07 | Flap mack | 02 | ||

| 02 | Double needle | 01 | Fixed bar | 153 |

| 02 | Angular | 69 | ||

| 03 | Folder type | 00 | ||

| 03 | Overlock | 01 | 4 thread | 113 |

| 02 | 5 thread | 376 | ||

| 03 | 6 thread | 48 | ||

| 04 | Vertical | 01 | Normal | 261 |

| 02 | Folder type | 14 | ||

| 05 | Kansai | 01 | Pmd | 45 |

| 02 | Smoking | 03 | ||

| 06 | Chain stitch | 01 | 1 needle | 06 |

| 02 | 2 needle | 79 | ||

| 03 | 3 needle | 27 | ||

| 07 | Snap button | 01 | Single head | 275 |

| 02 | Three head | 24 | ||

| 08 | Heat press | 01 | Normal | 20 |

| 02 | Head moving | 06 | ||

| 09 | Auto template sewing | 01 | Normal | 60 |

| 02 | Hidrolic cutting | 03 | ||

| 03 | Down feeding | 05 | ||

| 04 | Ricepiece four head | 01 | ||

| 10 | Flatlock | 01 | Flatbed | 08 |

| 02 | Cylinder bed | 00 | ||

| 03 | Loop flatlock | 07 | ||

| 11 | Feed of arm | 01 | Heavy | 28 |

| 02 | Light | 02 | ||

| 12 | Bar tack | 01 | Bar tack | 93 |

| 13 | Button stitch | 01 | Button stitch | 09 |

| 14 | Button hole | 01 | Buttonhole | 19 |

| 15 | Eyelet hole | 01 | Eyelet hole | 12 |

| 16 | Seam sealing | 01 | Seam sealing | 56 |

| 17 | Velcro attach | 01 | Velcro attach | 17 |

| 18 | Blind stich | 01 | Blind stich | 09 |

| 02 | Loop blind stich | 03 | ||

| 19 | Saddle stich | 01 | Saddle stich | 01 |

| 20 | fabric inspection | 01 | Fabric inspection | 04 |

| 21 | Piping cutter | 01 | Viyes cutting | 01 |

| 02 | Viyes rolling | 02 | ||

| 22 | Cutting machine | 01 | Auto cutter | 02 |

| 02 | Hand cutter | 19 | ||

| 23 | Fusing machine | 01 | Fusing machine | 03 |

| 24 | Automatic lay machine | 01 | Automatic lay machine | 03 |

| 25 | Band knife | 01 | Band knife | 01 |

| 26 | Metal ditector | 01 | Metal ditector | 07 |

| 27 | Hangtag | 01 | Hangtag | 00 |

| 28 | Label cutter | 01 | Label cutter | 00 |

| 29 | Velcro cutter | 01 | Velcro cutter | 04 |

| 30 | Water test | 01 | Water test | 02 |

| 31 | Thread recon | 01 | Thread recon | 08 |

| 32 | Label cutter(auto) | 01 | Label cutter(auto) | 02 |

| 33 | Zik zak | 01 | Zik zak | 05 |

| 34 | F.welding | 01 | F.welding | 02 |

| 35 | Sleep attch | 01 | Sleep attch | 03 |

| 36 | Westech m/c | 01 | Westech m/c | 04 |

| 37 | Button wrapping | 01 | Button wrapping | 02 |

| Total machine | 4445 |

Report

- Environmental Sustainability Report2016 Download

- ENERGY CONSUMPTION 2016 Download

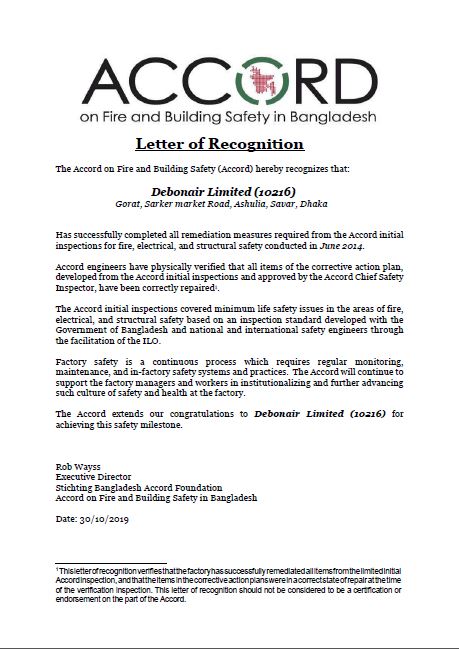

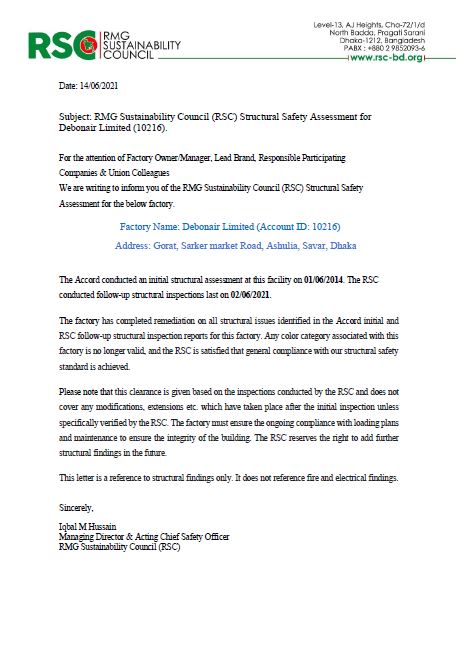

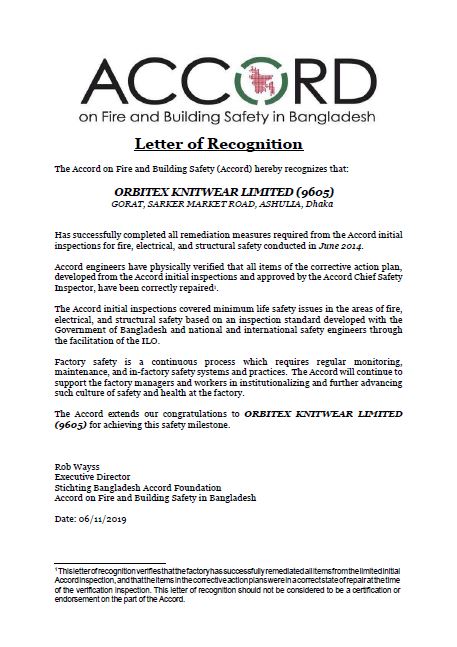

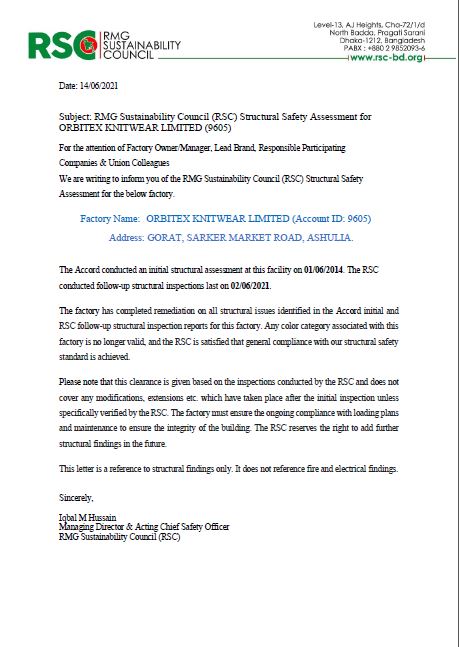

- Structural Assessment Letter Form ACCORD Download

- BSCI Audit Report Download

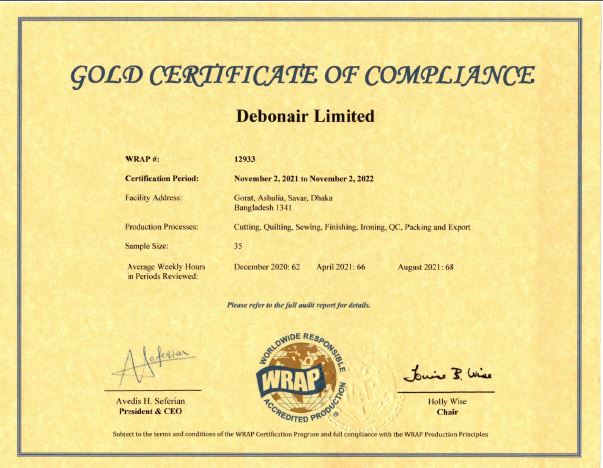

- WRAP Certificate Download

- COVID 19 Download

- About COVID 19 Eng. Download

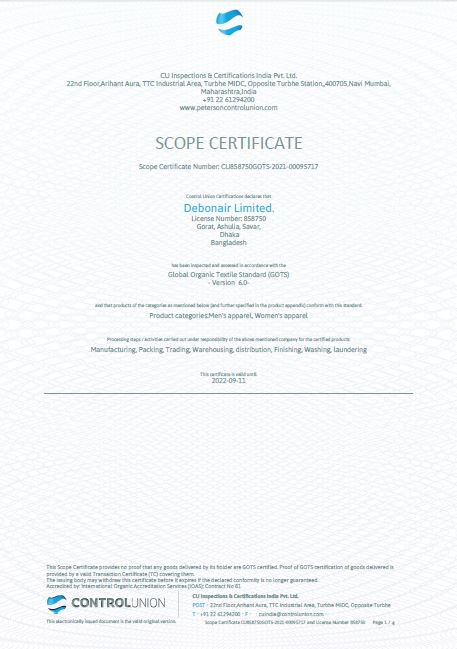

- GOTS 1 Download

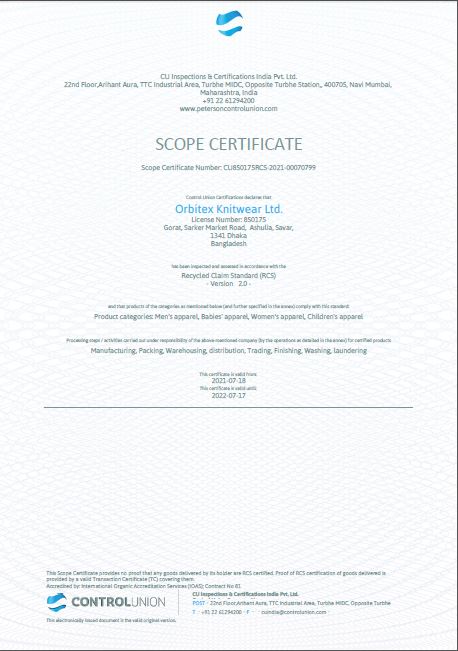

- GRS Download

- RDS Download

- Structural Assessment Letter Form ACCORD Download

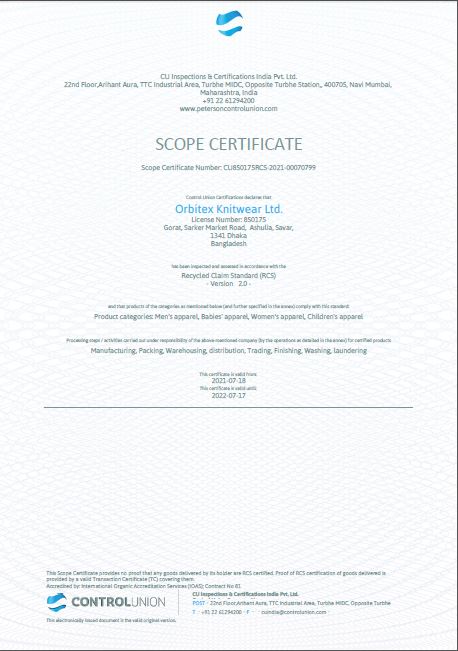

- RCS Certificate Download

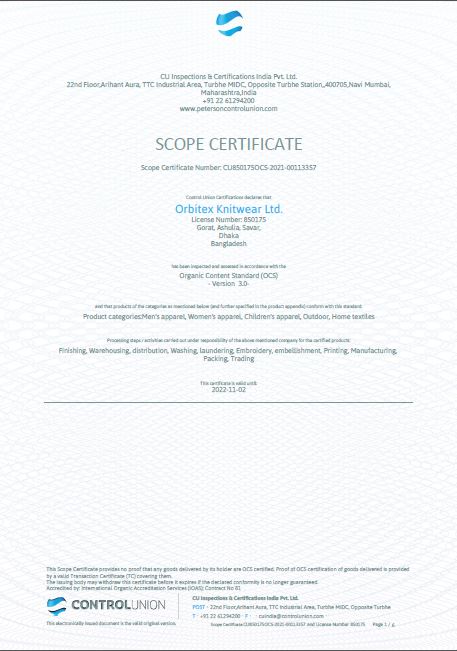

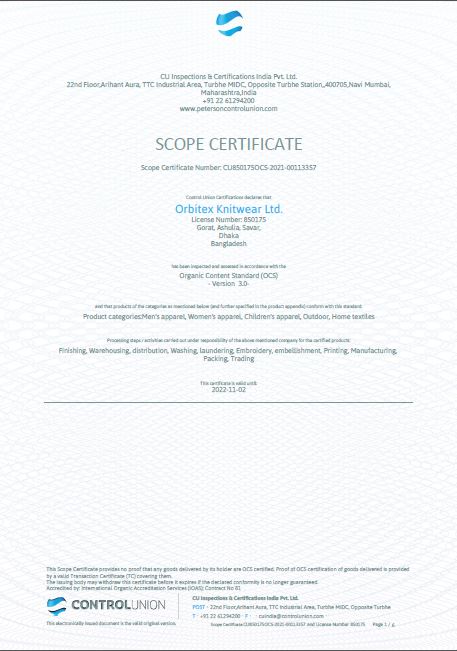

- OCS Certificate Download

- OCS Download

- RCS Download

Galleries

LOCATION

Address: Debonair Ltd. & Orbitex Knitwear Ltd. : Gorat, Sarker Market Road, Ashulia, Savar, Dhaka-1341

Certificate